Every industry, every product and even different countries require their own specific processing solutions. To this end, Tinxuan offers a variety of machines in numerous designs. They all share, however, one overriding characteristic: outstanding build quality for extra long life. Add simple operation, and Tinxuan machines are the perfect solution for every process industry.

- Lowest energy consumption thanks to high-quality technical solutions

- Lowest maintenance costs

- Strong, reliable machines

- Compact, space-saving solutions

- Ease of use

- Consistent production quality

PELLET MILLS

FEEDERS & CONDITIONERS

Tinxuan conditioners provide the optimum preparation of raw materials prior to pelleting in the Feed, Oilseed, Biomass and other industries. The optimum conditioning of the product ensures you to get the highest performance out of a Tinxuan pellet mill.The gain of good conditioning is a higher production throughput,

Tinxuan conditioners provide the optimum preparation of raw materials prior to pelleting in the Feed, Oilseed, Biomass and other industries. The optimum conditioning of the product ensures you to get the highest performance out of a Tinxuan pellet mill.The gain of good conditioning is a higher production throughput,

CLEANING

EXTRUSION

HAMMER MILLS

MIXING

Highly efficient mixers with feed-to-food safety standard for animal feed, food and pet food industries. High homogeneity : Patented double-circle paddle rotor - Hygienic design : Optimized paddle-to-wall gap and fully open discharge doors, no residue, no contamination; unique air-sac seal, no leakage; optional corrosion-resistant steel design.

Highly efficient mixers with feed-to-food safety standard for animal feed, food and pet food industries. High homogeneity : Patented double-circle paddle rotor - Hygienic design : Optimized paddle-to-wall gap and fully open discharge doors, no residue, no contamination; unique air-sac seal, no leakage; optional corrosion-resistant steel design.

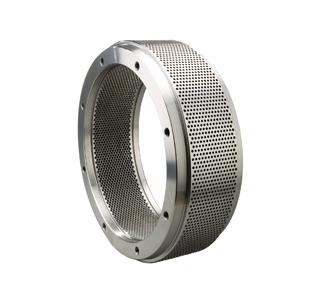

As the world’s largest manufacturer of pellet mills, Tinxuan has led the way in developing specialised pellet mills and dies to make pelleting both practical and economical while enhancing product value and manageability in the Feed, Oilseed, Biomass and other industries.

As the world’s largest manufacturer of pellet mills, Tinxuan has led the way in developing specialised pellet mills and dies to make pelleting both practical and economical while enhancing product value and manageability in the Feed, Oilseed, Biomass and other industries. Our pellet cleaning sieve is mainly made of the sieve cylinder drive mechanism,charging device,dedust device and sieve surface cleaning mechanism. It is a cleaning equipment, using rotary cylinder sieve surface to screen by itself,suitable for cleaning big sundries and light sundries of grain.

Our pellet cleaning sieve is mainly made of the sieve cylinder drive mechanism,charging device,dedust device and sieve surface cleaning mechanism. It is a cleaning equipment, using rotary cylinder sieve surface to screen by itself,suitable for cleaning big sundries and light sundries of grain.

Since many years, hammermills are used in various industries and nowadays often play an important role in production facilities. The most hammermill grinders are used in the animal feed industry, but also in other industries like Biomass, hammermills are found.

Since many years, hammermills are used in various industries and nowadays often play an important role in production facilities. The most hammermill grinders are used in the animal feed industry, but also in other industries like Biomass, hammermills are found. Widely used for cooling granular feed, Compact structure, small space occupied, Octagonal cooling bin, eliminating death corner, Reciprocating grid for smooth and uniform discharge flow, Little maintenance required and low energy cost.

Widely used for cooling granular feed, Compact structure, small space occupied, Octagonal cooling bin, eliminating death corner, Reciprocating grid for smooth and uniform discharge flow, Little maintenance required and low energy cost. Maintenance is necessary for every machine after working a period of time. We supply pellet mill parts including pellet mill dies, pellet mill rolls, roller shell, bearings, shafts, etc.

Maintenance is necessary for every machine after working a period of time. We supply pellet mill parts including pellet mill dies, pellet mill rolls, roller shell, bearings, shafts, etc.